Once all of the clamps were off I stood back and admired all of the hard work I had put in and all of the patience I had given to the board. I picked the board up, I tucked it under the arm dreaming of the first time I will take it out, I ran my hands over its surfaces (WAIT A MINUTE! What is this)?

The keel section at the nose with the most camber is not adhered to the deck!

What happened?

Most importantly, WHAT DO I DO?

I did the only thing I knew to do. Put the clamps back on as quickly as possible. It was too late to call Grain that day, so I waited and tried to not think about it until the next day. After having a fitful night I got in touch with Mike at Grain and his tone put me at ease. We discussed what exactly happened and found out that if you have to buy a second tube of 3M 5200 you have to make sure you get the fast cure and not the 7 day cure version if you want to take the clamps off after 24 hrs. Otherwise, You have to wait a full week. That was O.K. because I had other things to do, but when you get on a role and you are at this stage of the build you don't want to have wait a week for anything.

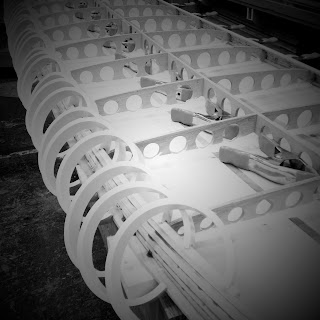

Well, I don't know if you can tell or not from the picture, but everything worked out. This really taught me a lot. I learned that you should always read directions no matter how much of a hurry you are in. Follow the directions. Never assume anything is good until you check it for yourself (if I would have walked away from the board with out really looking it over I would have missed the issue and come back after the weekend to horrific disappointment). And finally, I learned, and I have been learning throughout this entire project, that if you slowdown and take it one step at a time and not get ahead of yourself everything will turn out fine.