Well, after the whole glue up scare I was able to pull myself together and start shaping my board. This, I have to admit, was a little nerve wracking because you spend all this time putting all of these pieces together and then now you have to take a blade to it and start cutting it down. Breath! Just do as the manual says and take it one step at a time.

Trying to take it slow so that I can always come back and remove more material. As a wood worker I learned long ago that you don't have a lot of sucess putting the wood back on after you remove it. This is also where my lack of knowledge starts to play evil tricks with me. Other than the directions in the manual and my small amount of experience surfing, I havn't the first clue how to shape a boards rails. Up until this point the rails were folowing the shape of the frames, but now I must fly solo and just let my instincts take over and trust that I have gleaned enough from the Grain super manual. Have you ever noticed that you can read something over and over and it still makes no sence to you, and then when you have left it and come back it all of a sudden is crystal clear ( well maybe crystal is an over statement ).

I did a little playing and came up with a configureation for the tail block that I feel looks good with the boards stringer and jumped right into cutting the ass off of my board. Just go for it! Everyone who has built a board has had to do the same thing, I am not the first. I'm sure I'm not the first guy or girl to get a little nervous as the process continues. Every hour you put into the project is one more step closer to something that you don't want to screw up!

Glue the blocking! Glue the blocking to the board! Shape the blocking!

Hey! Wait a minute! This is starting to look like a surf board!

wood to water

Sunday, July 22, 2012

Monday, June 25, 2012

The Great 3M Debacle! Well, almost.

This story begins about twenty three and a half hours after I glued the top plank onto my board. The glue up went very smoothly, as planned (everyone should do a dry run before doing something this involved and important). I very patiently waited the day through to take off the 100 clamps that were holding the board together (you truly can never have too many clamps).

Once all of the clamps were off I stood back and admired all of the hard work I had put in and all of the patience I had given to the board. I picked the board up, I tucked it under the arm dreaming of the first time I will take it out, I ran my hands over its surfaces (WAIT A MINUTE! What is this)?

The keel section at the nose with the most camber is not adhered to the deck!

What happened?

Most importantly, WHAT DO I DO?

I did the only thing I knew to do. Put the clamps back on as quickly as possible. It was too late to call Grain that day, so I waited and tried to not think about it until the next day. After having a fitful night I got in touch with Mike at Grain and his tone put me at ease. We discussed what exactly happened and found out that if you have to buy a second tube of 3M 5200 you have to make sure you get the fast cure and not the 7 day cure version if you want to take the clamps off after 24 hrs. Otherwise, You have to wait a full week. That was O.K. because I had other things to do, but when you get on a role and you are at this stage of the build you don't want to have wait a week for anything.

Well, I don't know if you can tell or not from the picture, but everything worked out. This really taught me a lot. I learned that you should always read directions no matter how much of a hurry you are in. Follow the directions. Never assume anything is good until you check it for yourself (if I would have walked away from the board with out really looking it over I would have missed the issue and come back after the weekend to horrific disappointment). And finally, I learned, and I have been learning throughout this entire project, that if you slowdown and take it one step at a time and not get ahead of yourself everything will turn out fine.

Thursday, June 7, 2012

The end is the beginning is the process

I came home with a freezer full of salmon and a burning desire to go back (I think 2013). Then I spent a little time in one of my favorite states, Washington. My wife and I went to what we would find out to be the last Journalfest in Port Townsend. We were able to spend some great days with what I consider some of the best friends you could ask for. After the Holidays we went to Florida to see family in two locations up and down the coast with a little majic in the middle. That's right, we went to Harry Potter World at Universal Studios Orlando. Good times and great relaxation. March saw me back in Washington for the final Artfest and more creative time with great friends. Then, May. Trip to Texas to see more family and friends. It's the first week in May and I am not ready for 90 degree weather. I guess that is why I moved out of Texas.

Well while all of this was going on I did manage to get a little work done on my waterlog. First I moved the whole shooting match up to my shop where I work so I could have some heat during the winter months, it is Colorado. I have to admit I got a little bogged down with the railing process but eventually got some steam and finished the glue up. I don't know how they teach this class in a week. I guess I am just a little too retentive to work that fast.

After this I got to start some pre shaping and really got to start seeing the fruits of my labor.

Next Time we'll talk about the top and how much fun it is to get to the point where foam board builders start their boards.

Thursday, September 8, 2011

Learning a new Art

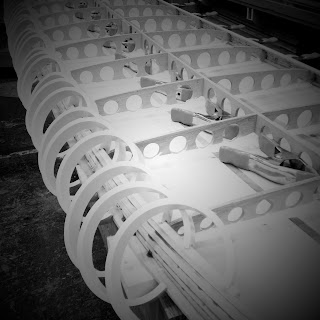

O.K. how many of you "Grain Surfboard" builders out there have done this. You get your kit in the mail and the first thing you do is put together the keel and frames to try and get a look at what your new board is going to look like. Well, I bought my kit a year ago so you can imagine how many times I have done this. Now is when I tell you that I have finally put together this assembly for the last time and glued it to the bottom plank.

This is definitely not a solo project. I mean, I can surely build this board by myself but there are just some tasks that simply require more than two hands. Clamping down the frames is one of them. With fifteen frames and two clamps for each frame, that just proves that you can never have too many clamps.

Clamps are off and everything looks good. On to the next step. I was reading ahead and realized that it is going to be alot of "On to the next step". I think this is a real good thing for me. I can set my own pace and learn the art of delayed gratification.

This is definitely not a solo project. I mean, I can surely build this board by myself but there are just some tasks that simply require more than two hands. Clamping down the frames is one of them. With fifteen frames and two clamps for each frame, that just proves that you can never have too many clamps.

Clamps are off and everything looks good. On to the next step. I was reading ahead and realized that it is going to be alot of "On to the next step". I think this is a real good thing for me. I can set my own pace and learn the art of delayed gratification.

Thursday, August 18, 2011

Getting off the ground (being grounded)

Well, this week has been a good one. After the hair raising task of trying to glue up 9 ten foot long planks to create the bottom panel, and race to get the excess glue off before the heat and lack of humidity set up the glue, I was able to get the bottom cut to rough size and sand out any uneven edges. Now I am getting excited! For the first time I can start to see the outline of the board and imagine myself padeling out.

The sanding of the inside edge was O.K. but it made me realize that it was probably time to invest in some hand planes. I will need them eventually, and there is no time like the present. While those are on order I went ahead and glued up the top planks so that I could reuse a lot of the wood from the laminating table to create my rocker table. Once that was done it was time to remove the tape that helped to hold the joints together. Call me wierd, but this was very satisfying. Not that it revieled anything new, just the process of pealing off the tape itself. I think it is kind of kin to when you get a sunburn or a scraped knee, you just can't help it.

Now I can turn to the rocker table and the keel and frame construction. I am finding this process very calming, a real step away from all of the hustle bustle of everyday stress. This is good for me, I need something to slow me down and ground me.

Don't you just love the way the knots and grain give such character to the board?

The sanding of the inside edge was O.K. but it made me realize that it was probably time to invest in some hand planes. I will need them eventually, and there is no time like the present. While those are on order I went ahead and glued up the top planks so that I could reuse a lot of the wood from the laminating table to create my rocker table. Once that was done it was time to remove the tape that helped to hold the joints together. Call me wierd, but this was very satisfying. Not that it revieled anything new, just the process of pealing off the tape itself. I think it is kind of kin to when you get a sunburn or a scraped knee, you just can't help it.

Now I can turn to the rocker table and the keel and frame construction. I am finding this process very calming, a real step away from all of the hustle bustle of everyday stress. This is good for me, I need something to slow me down and ground me.

Don't you just love the way the knots and grain give such character to the board?

Monday, August 1, 2011

Summertime in Colorado

After spending a little time reading the manual and collecting some tools and supplies, I finally was able to start making a little sawdust (sordust). I started by milling up some walnut for the stringer details that I wanted to ad. Then the laminating table was built so that I could glue up my bottom planks.

The process of building this table is a bit of a zen practice when you are ready to start working on your board. Taking the time to get everything square and taped so that glue will not stick to the wood is half of the work. Now it is time to get a visual. Pulling out the bottom planks and laying them out to find the best configuration before glue up is really exciting.

The moment is finally here to take action on this quest to build this beautiful wood salt sled. After about what seemed like an hours worth of taping the seams for gluing I was able to finally pull the cork out of the old glue bottle. Lets get messy!

Now that all of that fun has been had the bottom blank is glued and clamped and left to sit for the night. I will check in on it tomorrow and think about glueing the top blank.

Subscribe to:

Posts (Atom)